Optical Coating: The Finishing Touch in Ultra-Precision Optics

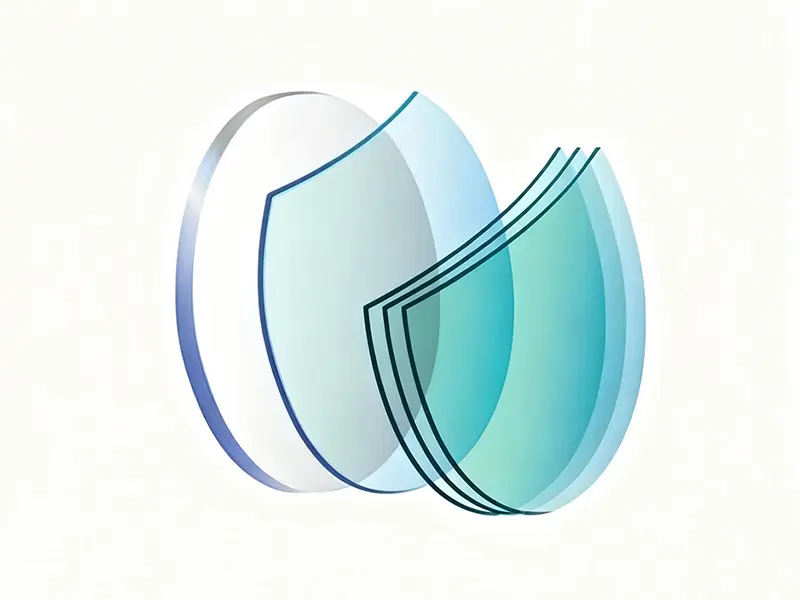

Surface coating for ultra-precision lenses is the final step in the manufacturing process. It is particularly critical. Only after the coating is completed will the performance of the lens substrate meet the standards and satisfy the requirements of the final optical system. Ultra-precision optical coating is far from being as simple as " coating film." It needs to be precise at the atomic level, precisely controlling the thickness, material, and structure of the coating layers to achieve specific optical properties such as ultra-high transmittance, ultra-high reflectivity, specific spectral ratios, and high environmental stability.

Faced with such strict requirements, no supplier dares to say "I can do whatever you want." More often than not, there is a contradiction between the desired effect and the realization of the process. This is why evaluations are conducted with extreme caution. Yet, precisely this pursuit of the ultimate drives ultra-precision optics to continually break through technical limits.

Nowadays, ultra-precision optical coating technologies have advanced significantly. The following section will focus on the introduction of the mainstream optical coating techniques.

1. Physical Vapor Deposition (PVD)

Physical vapor deposition (PVD) is currently the most mainstream technique for ultra-precision optical coating, employed to deposit multilayer films onto optical components with atomic-level precision. The most common techniques include advanced Electron-Beam (E-beam) Evaporation, Ion-Assisted Deposition (IAD), and Ion Beam Sputtering (IBS).

1) E-beam Evaporation

Principle:

In a vacuum chamber, coating materials (e.g., SiO₂, Ta₂O₅, HfO₂) placed in a water-cooled crucible are bombarded by a high-energy electron beam, causing them to instantly heat, melt, and vaporize. The vaporized material atoms deposit on the surface of the rotating substrate, gradually forming a film.

Pros:

• It offers a relatively high deposition rate and can handle high-melting-point materials.

• High purity (avoiding contamination from resistance heating sources).

Cons:

The coated film is usually columnar porous and not dense enough. This will lead to moisture adsorption and optical property drift.

2) Ion-Assisted Deposition

Principle:

IAD is a revolutionary upgrade based on traditional electron beam evaporation and has become a standard technique for modern ultra-precision coating. While the material is being evaporated, a separate ion source (such as a Kaufman source) generates a high-energy inert gas ion beam (e.g., argon ions) to continuously bombard the growing film during deposition.

Core Functions of Ion Bombardment:

1. Increase film density: High-energy ions drive deposited atoms into more stable positions, disrupt their natural columnar structure, and form a dense, durable, and environmentally stable coating.

2. Reduce internal stress: The film stress (compressive stress or tensile stress) can be controlled by adjusting the ion energy and flow rate.

3. Enhance adhesion: Ions clean and activate the substrate surface, ensuring a stronger bond between the film layer and the substrate.

4. Stabilize optical performance: The dense film adsorbs almost no moisture, ensuring extremely stable performance.

Features:

IAD technology greatly enhances the film's mechanical properties and environmental stability, making it one of the preferred technologies for manufacturing high-performance laser optics and astronomical filters.

3) Ion Beam Sputtering

Principle:

IBS is currently recognized as the highest-precision coating technique. It uses a high-energy ion beam (usually argon ions) to bombard the target material (coating material), and ejects target atoms via the physical sputtering. These sputtered atoms possess high energy and then deposit onto the optical substrate to form a film.

Characteristics:

1. Ultimate Precision: The deposition rate is slow and extremely stable, allowing for atomic-layer level control of film thickness. It can produce films with the sharpest interfaces and the most uniform layers.

2. High Density: The sputtered atoms produce dense and smooth films with unparalleled stability.

3. Extremely Low Loss: Due to extremely low absorption and scattering, lenses coated by IBS can achieve a reflectivity of over 99.999%, such as those used in gravitational wave detectors like LIGO, or an extremely high laser-induced damage threshold (LIDT).

Disadvantages:

Expensive equipment; slow deposition rate; high cost.

Applications:

It is applied in the most high-end fields, such as extreme ultraviolet (EUV) lithography machines, gravitational wave detection, quantum optics, and high-stability space optical systems.

2. Atomic Layer Deposition (ALD)

ALD technique is less common for ultra-precision optics due to its specific limitation.

Principle:

This method builds films through self-limiting chemical reactions. Precursor gases A and B are alternately pulsed into the reaction chamber. Each pulse only chemically adsorbs a single atomic layer on the substrate surface. Then, an inert gas is used to purge excess precursors. With each cycle of "A-pulse - purge - B-pulse - purge", a compound thin film is precisely grown.

Characteristics:

1. Unparalleled Uniformity and Consistency: It can achieve perfectly conformal and uniform coating even on complex structures such as deep holes and high aspect ratios, which is impossible for PVD technology.

2. Atomic-Level Thickness Control: The film thickness is only determined by the number of cycles, with a control precision reaching a single atomic layer.

3. High Film Quality: No pinholes, good density.

Disadvantages:

Extremely slow deposition rate. It has a limited choice of precursor materials.

Applications:

It is more inclined to be used for functional thin films rather than traditional optical films, such as in micro-nano optics, photonic crystals, and depositing extreme protective layers on existing optical films.

Now that we've covered the ultra-precision coating technologies, do you know what their core technical elements are? It's important to note that, regardless of the technology used, achieving ultra-precision coating requires the following key elements:

1. Precise Film Thickness Control System

• Optical monitoring method: During the coating process, a monochromatic laser is used to monitor the real-time changes in the transmittance or reflectance of a witness sample. Deposition stops when an extreme value is reached. This method offers the highest precision and is suitable for complex film systems, but it requires high operator experience.

• Quartz crystal monitoring method: The frequency change of a quartz crystal oscillator is used to measure the deposited mass thickness in real time. It is simple to operate and suitable for large-scale production, but the tooling factor for different materials needs precise calibration

2. Ultra-High Vacuum Environment

The vacuum degree of the chamber needs to reach the 10⁻⁵ Pa (10⁻⁷ mbar) to ensure that the average free path of the deposited atoms is long enough to avoid collision with residual gas molecules, thereby guaranteeing the purity and density of the film layer.

3. Advanced Plasma/Ion Source:

This is the "soul" of modern coating technology. It determines the controllability of ion energy and flow rate, and affects the film quality directly.

4. Precise Material Processing

The purity of the target material and evaporation material is extremely high (usually ≥ 99.99%). Any impurities can become absorption or scattering centers, reducing the laser-induced damage threshold (LIDT).

It can be seen that choosing a coating technique for ultra-precision lenses is not an easy task. This is a process of balancing performance, cost and cycle time. IBS technique represents the peak of optical coating precision, while IAD stands as the most mainstream and balanced choice for high-performance applications. Their common goal is to build a perfect artificial structure at the atomic scale, allowing light to propagate exactly as humans envision.